- Customer Services: +90(232) 461 87 71

- E-Mail: info@efecantozboya.com

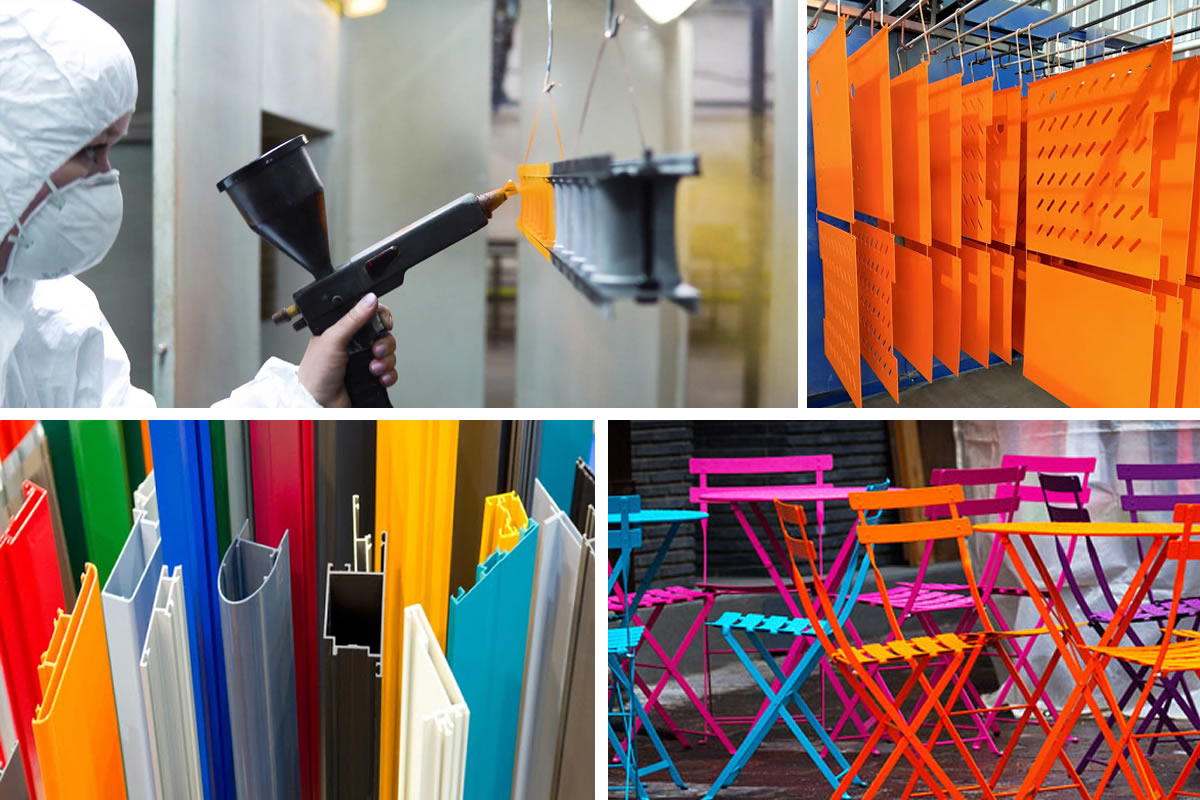

Electrostatic Powder Coating

Electrostatic powder paint is a solvent-free, environmentally friendly decorative and functional type of coating (paint) applied to metal or other conductive surfaces that are not liquid inside.

The emergence of powder paint is generally associated with the emergence of environmental and ecological sensitivity in the 1960-70s. A law enacted in Los Angeles in 1966 is the first law to consider and restrict the ecological aspect of dyes.

In 1964, the first epoxy powder paints came to the European market and started to spread rapidly.

In the same period, the electrostatic powder paint application system was developed and launched in France.

Powder Coating has been accepted worldwide in the 1970s and entered a growth process and has provided rapid technological development until today.

Application of Electrostatic Powder Coating

- Degreasing

- Chromating

- Iron Phosphating

- Zinc Phosphating

After the necessary chemical pre - treatment is applied, the part to be painted is taken to the paint booth, and the fine electrostatic powder paint particles are loaded with(-) load while passing through the special gun produced for powder paint, and the static paint sticks to the material because the material to be painted is also grounded.

Since all of the particles are loaded with the same load, the material is placed in the oven at 200 ° C - 240 ° C for curing after the material is distributed homogeneously over the entire surface by pushing each other and is kept in the oven for a certain minute according to the curing property of the paint. During the waiting phase, the electrostatic powder paint melts (cured) It covers the desired color in a smooth and durable way. The coated material is taken from the curing oven to the cooling line and made ready for use.

Reasons for Choosing Electrostatic Powder Coating

- Electrostatic powder paint is ecologically sensitive to the environment,

- Electrostatic powder paint has a wide range of color options,

- Smooth and glossy surface quality,

- Corrosion resistance,

- Electrostatic powder paint is resistant to chemical effects,

- It is preferred by different sectors due to its resistance to impacts.